Illinois soybean farmers can expect breakthrough innovations and brand-new commercial products from an emerging partnership between Illinois Soybean Association (ISA) and the Peoria-based National Center for Agricultural Utilization (NCAUR) in Peoria, Ill.

The 270,000-sq.-ft. research facility, part of the Agricultural Research Service (ARS) at the U.S. Department of Agriculture (USDA), employs nearly 200 people including 75 Ph.D. scientists and highly trained technical support staff. They’ve been studying soybean use cases extensively for 60 years.

“Research at NCAUR is designed to address issues that are important to soybean farmers and everyone in the soy value-chain,” explains Dr. Todd Ward, NCAUR director. “The partnership with the ISA is a perfect fit for us because we share the same mission, developing and commercializing new value-added uses for soy. The goal is to increase economic opportunities for farmers and rural communities while providing sustainable biobased products and technologies to meet market needs.”

The lab’s successful track record and reputation makes it an ideal partner as ISA continues to investigate demand pathways as Illinois soybean production rises.

“This is one of the leading research facilities in the state and will be an important partner moving forward with our mission of developing new markets for Illinois soy,” says ISA Director of Market Development Todd Main.

New Product Opportunities

One of the partnership’s first research projects is to explore soy-based alternatives to PFAS, sometimes called forever chemicals. “PFAS has a $28-billion-plus market value,” Ward says, “yet manufacturers are eager to find alternative products amid persistent health and environmental concerns.”

“The true cost of PFAS, including water and environmental remediation and health care costs associated with PFAS exposure are estimated to be trillions of dollars,” Ward explains. “We are therefore planning to use soybean oil to produce renewable, nontoxic, and biodegradable PFAS replacements for food packaging and coatings applications.”

“Soy-based solutions could also support products as diverse as textiles, cookware, cosmetics and firefighting foams,” he adds.

Another area of focus for the partnership will be continued diversification of soy meal applications.

“Expanding markets for soybean oil will drive the need for research to develop highvolume and value-added applications for soybean meal components,” Ward says. “Our plant polymer team is particularly interested in this area of research, and they are developing new research programs designed to address this specific issue.”

Beyond research, NCAUR researchers seek to learn more from ISA about soybean industry needs, markets and commercialization barriers. The facility can then adapt its research focus to address those emerging opportunities and challenges.

“This is an important and valuable asset for developing new markets for soy,” Main says.

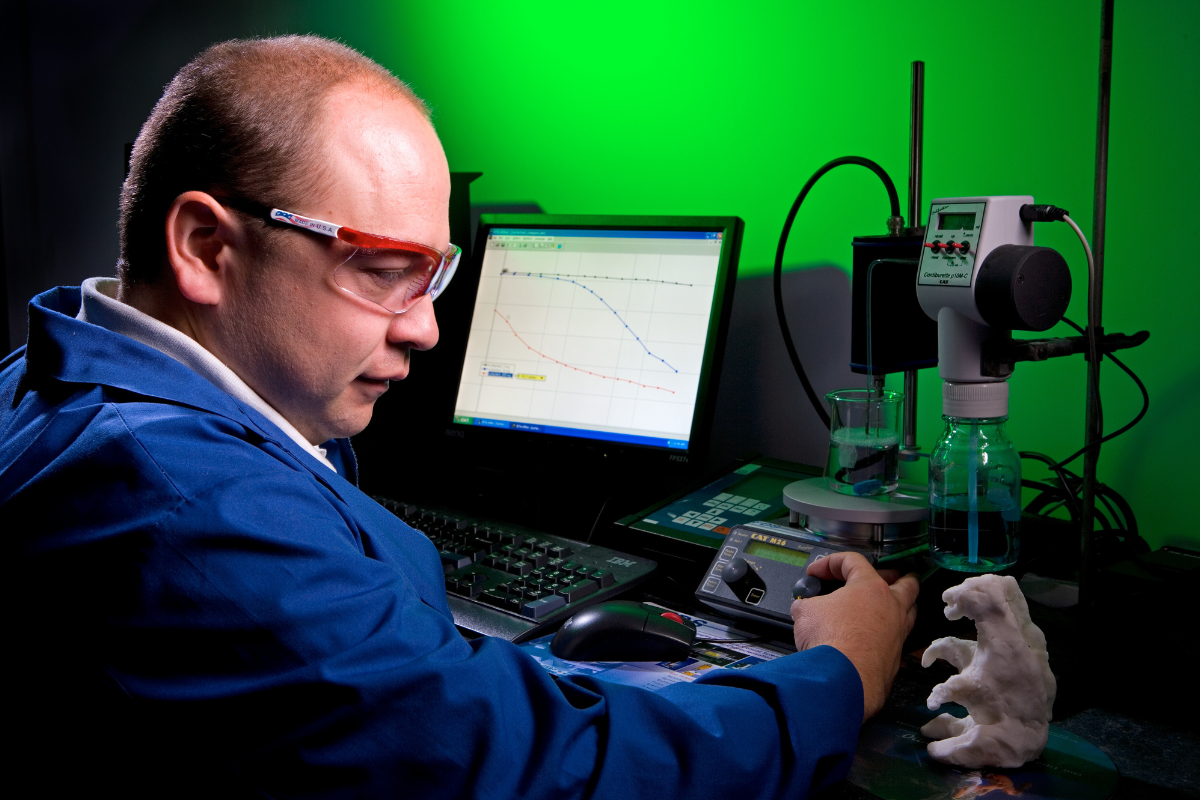

Dr. David Compton, a researcher in NCAUR’s Renewable Product Technology Research Unit, processes modified soybean oil into sunscreen.

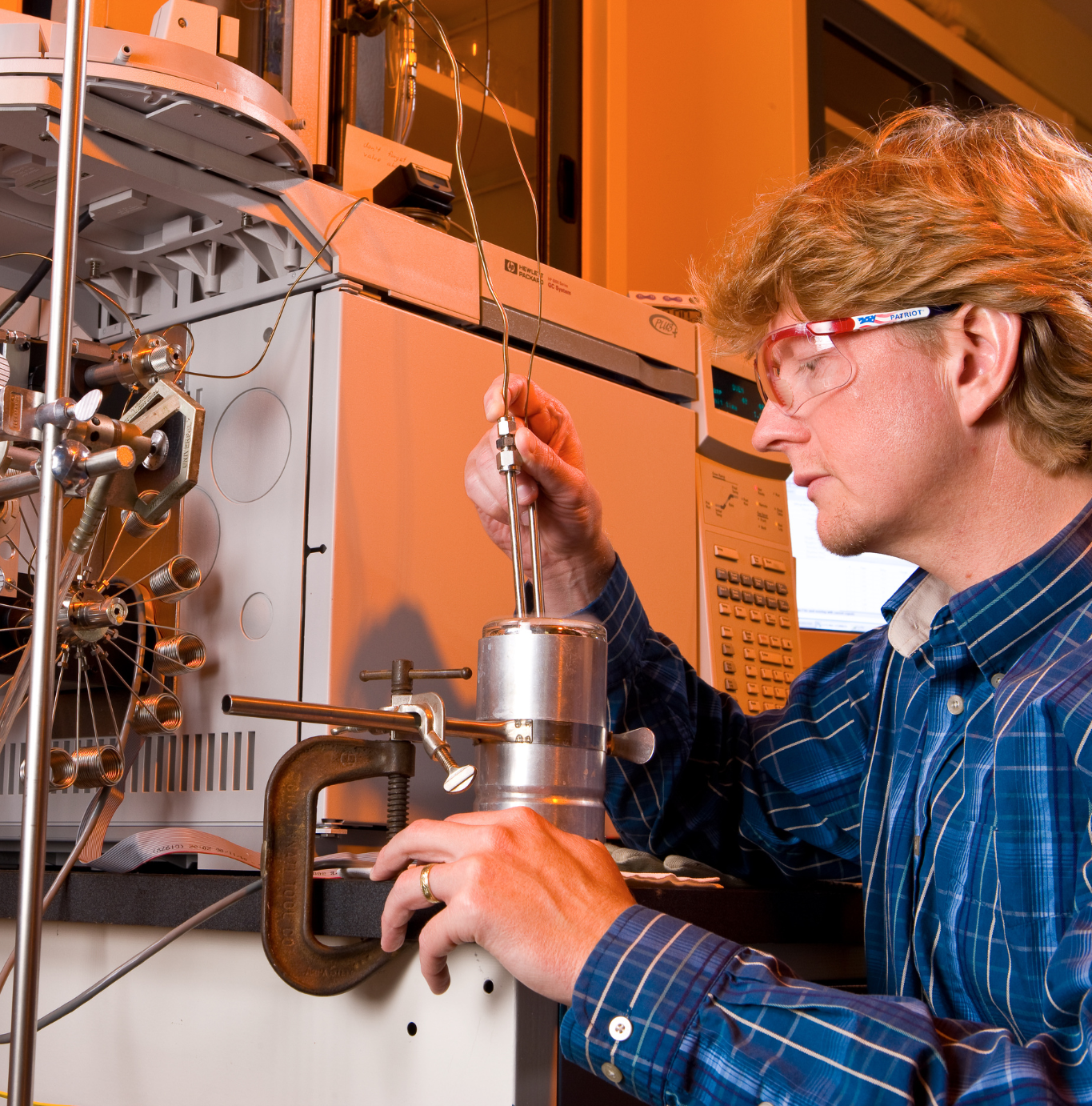

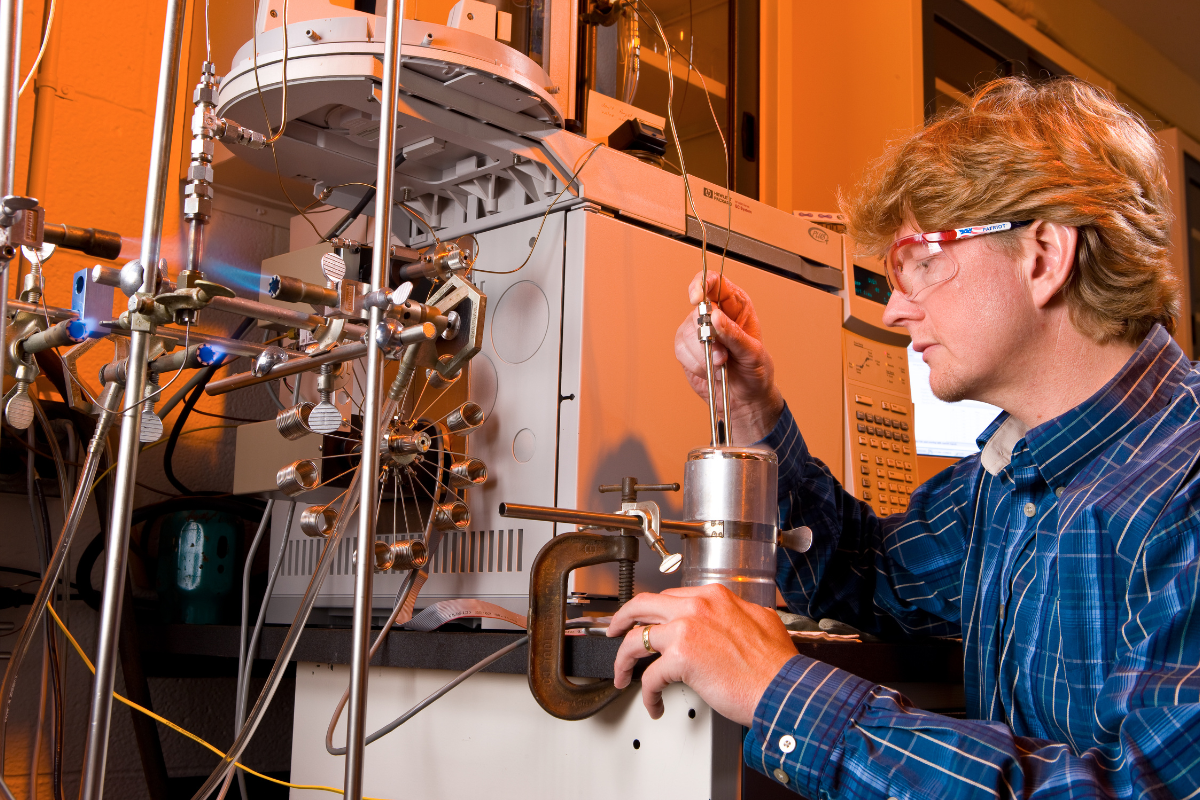

Dr. Kenneth Doll, formerly of the Bio-Oils Research Unit, measures the properties of modified soybean oil at NCAUR

Expertise and Equipment

“What sets the NCAUR facility apart from other research labs is its deep bench of expert talent committed to advancing ag to address issues of national and international importance,” says Ward, who has a background in genetics and microbiology. Before directing the lab, he worked for 20 years as a USDA researcher improving food safety and crop production.

An array of technical equipment also helps researchers conduct deep studies and even pilot new products that can be scaled and commercialized by industrial partners.

“These include equipment for melt extrusion for producing bioplastic, biocomposite, and foamed bioplastic samples; industrial-scale injection and compression molding equipment; and microfluidizer equipment for producing nanocellulose from agricultural materials and wastes,” Ward explains. “Additionally, NCAUR contains specialized equipment for the determination of fuel, lubricant, surfactant and polymer properties of soybean materials.”

The facility’s researchers have led multiple breakthroughs over the decades, a pattern the ISA partnership will advance.

“In the 1950s, NCAUR scientists were already doing research on soybean proteins and were among the first to establish the composition, structure, nutritional quality and functional properties of soybean proteins,” Ward says. “They also developed bench-scale methods to extract the protein and produce protein concentrate.”

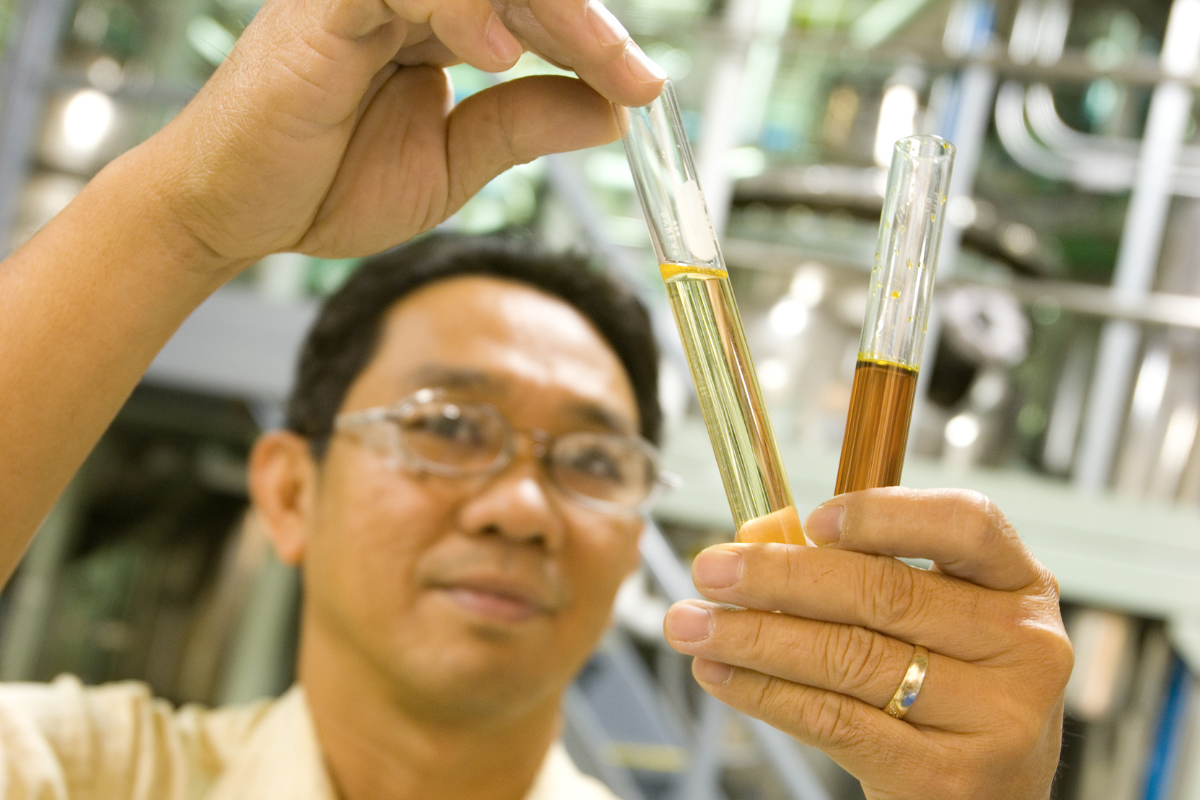

Dr. Roque Evangelista, a researcher in NCAUR’s Bio-Oils Research Unit, compares soybean oil with wild pennycress oil in the NCAUR Bio-Oils Pilot Lab.

Innovation Horizon

Looking ahead, Ward is energized about several of the lab’s additional ongoing areas of study focused on soybean market diversification, particularly in value-added soy oil applications.

Among the applications he highlights:

- Renewable Monomers: By 2031, the global monomer market is expected to reach more than $58 billion. Monomers are the building blocks for polymers, which make up textiles, plastics, adhesives, coatings, paints and packaging materials. Petroleum and natural gas are used almost exclusively as polymer feedstocks today, a key opportunity for soy.

- Composites: “Food packaging is a $360 billion market and is expected to grow 5.7% through at least 2030,” Ward says. It provides extended shelf life, handles high moisture levels, resists grease and ensures food safety. Biodegradable soy oil could increasingly replace packaging materials that are currently singleuse and nonrenewable.

- Epoxy Resins: These materials go into adhesives, paints and coatings, providing them with high strength, stiffness, topnotch electrical performance and high chemical resistance. They represent a combined market of $261 million that’s anticipated to grow between 6% and 7% annually through 2030. Yet today, most are petroleum-based and contain bisphenol A (BPA), which is toxic and does not biodegrade. Soy could provide comparable or superior performance.

- Hydroxy Fatty Acids: Castor oil from Brazil, China and India can be synthesized for use in lubricants, grease, cosmetics and polymers. The market for one such hydroxy fatty acid, ricinoleic acid, is anticipated to grow from $2.2 billion in 2023 to more than $3.8 billion by 2032, yet poses agronomic and human-health problems. Thus, the lab has developed a system that creates these acids from soy oil at a competitive price to castor oil. All these and other research opportunities will continue to benefit from close collaboration with Illinois soybean farmers and the broader ag community.

“The ISA partnership is a major benefit to us because it provides us with information that will help us develop research programs that have a direct and positive impact on the soybean industry,” Ward says. “USDA research programs are responsive to stakeholder input, and I encourage Illinois soybean producers and the ISA to continue to make their priorities known to USDA scientists and leadership.”

Photos credit: BAUER Photographics, Inc.

Recent Articles

TikTok sensation Jackson Laux, age 9, partners with John Deere to inspire agriculture's future.

By IL Field & Bean Team

From cutting-edge research to hands-on support, discover the vital role Extension plays in improving farm operations and advancing Illinois agriculture.

By Talon Becker, Commercial Agriculture Specialist, University of Illinois Extension