Heightened marketplace interest in sustainable products, including a push to replace petroleum with renewable ingredients, means opportunity for Illinois soybean farmers. As the Soy Innovation Center (SIC) overseen by Illinois Soybean Association (ISA) marks its one-year anniversary in March 2025, those closest to the initiative say there are plenty of reasons to be optimistic about the economic potential for meeting that demand.

“Overall, if we look at the last 50 years of soybean demand, first was naturally the meal. It was the driver for livestock, and the oil was kind of a leftover product,” explains Steve Pitstick, an ISA Board Director and farmer who grows 6,000 acres of corn and soybeans about an hour west of Chicago with his son, Dale. Now soy oil, “through ingenuity and work with the different associations, got things going.”

If favorable rules and tax incentives keep pushing oil demand for fuel, for instance, it could be that meal becomes the soy product in need of new buyers. The SIC will help Illinois soybean farmers pivot to meet the market by exploring opportunities across all soy products, “working with innovators within the industry, ag tech firms, startups, the U.S. Department of Agriculture lab in Peoria [see page 14 for complete details],” Pitstick explains.

From Insight to Innovation

The idea that led to the founding of the SIC—which is made up of experts and research labs instead of having a physical headquarters—came from Pitstick, a farmer who’s worked in ag tech and has a patent related to agronomic processes. Those experiences exposed him to the value of bringing talented experts and researchers together to innovate new products.

“I kept thinking, ‘We need to search out people at the universities, people in industry, people in labs, wherever, and show them what we have,’” Pitstick recalls. “We have this product, soybean meal and soybean oil. ‘What can you do with it?’ They may not be familiar with it. It might not be on their scope of thought.”

At the time, Pitstick served as ISA’s Chairman.

“The startup was approved for fiscal year 2024, and we began work in September,” explains ISA Director of Market Development Todd Main. “The SIC was formally launched in March, and we completed our first successful research and development work on a soy-based biolubricant for use in heavy machinery in the fall of 2024.”

Now, Pitstick and Main are among a large network of ag professionals collaborating with partners such as Airable Research Lab to unlock new demand for Illinois soybeans and for the crop broadly across the U.S.

“The SIC is dedicated largely to the commercialization and widespread adoption of soy-based materials and technologies, providing both consulting and financial support to the innovators behind those products,” explains Founder and Chief Laboratory Officer Barry McGraw of Airable, a soybean R&D laboratory started roughly five years ago by the Ohio Soybean Council. It is currently funded by seven soybean state checkoff organizations and is working closely to advance the SIC’s mission. “The SIC acts as something of a hub, using its extensive resources—facilities, a trained workforce, access to funding, and other stakeholder contacts—to spur every stage of innovation.”

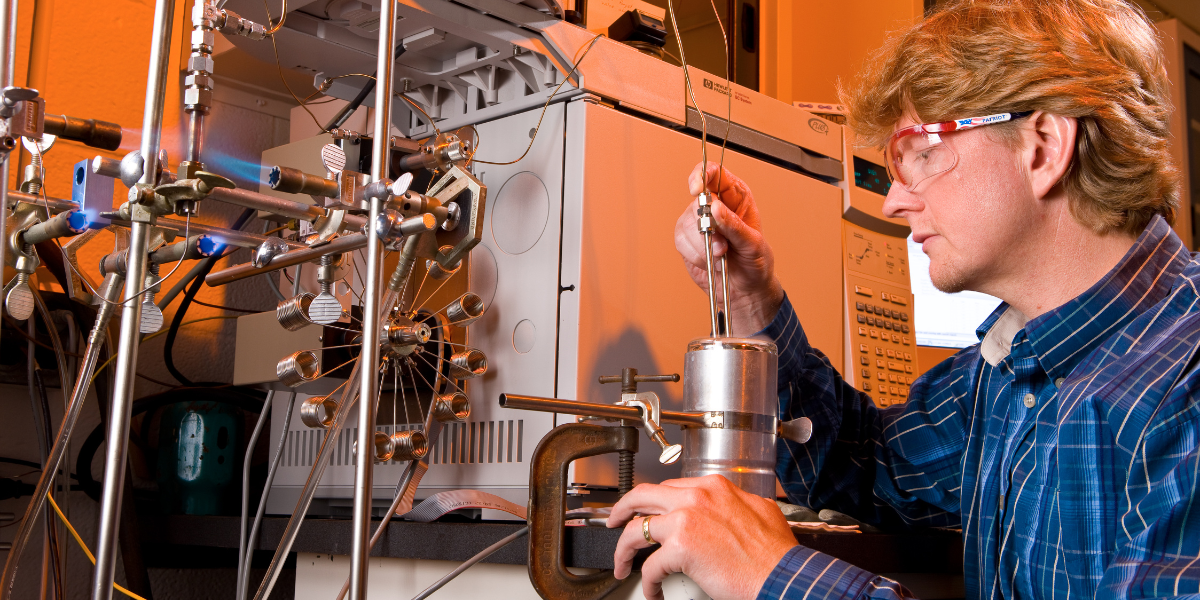

An Airable scientist determines the melting parameters of a soy-based monomer at the company’s Ohio headquarters. Photo credit:

Airable Research Lab

Rise of the Biobased Economy

Interest in biobased products has emerged over the past several decades, McGraw says. For many years, government agencies in the U.S. and globally have helped nudge the soybean industry in that direction.

“Governments have tried to regulate the economy into sustainability, and although that’s not the most efficient or effective approach, it does encourage industry to start making preparations,” he says. “The government has also invested significant resources into greener products and processes, helping to set the stage for the transition away from substances that are unhealthy for our planet and our people.”

Yet the biggest factor directing soy to explore new commercial opportunities is the demand of people who live in those countries.

“At the end of the day, companies answer to consumers, and consumers are becoming more environmentally conscious and willing to pay a little more for sustainable products,” McGraw points out. “They see the issues with relying on petrochemicals and other feedstocks that have wildly varying availability and pricing. They’re ready to put their dollars toward greener, cleaner solutions that support the farmers right here at home. And of course, as biobased products enter the market, more consumers become aware of them and their benefits, and it becomes an upward spiral.”

For industry, that means it’s time to get in on the action or risk being left behind.

“Now that the market is opening up, all those years of preparation are paying off, as technology breakthroughs are making it possible to develop and produce biobased products cost-effectively—products that are just as good as, if not better than, their petroleum-based counterparts,” McGraw says.

Emerging Soy Use Cases

Of particular interest to researchers affiliated with the SIC are five soy-based product categories: plastics; lubricants; textiles; PFAS alternatives; and polymers, enzymes and resins.

Already, there have been significant wins.

For instance, ISA and Airable have developed a soy-based grease designed to function smoothly in harsh conditions involving extreme temperatures, corrosion and chemicals.

“The formulation meets requirements for both severe-duty wheel bearing and severe-duty chassis applications,” McGraw says. “The biobased formulation can displace petroleum-based oils and similar synthetic fluids and meets USDA BioPreferred® specifications.

Rough-and-tumble use cases for soy-based industrial applications extend beyond big machines to handheld ones, too. Outside of its work with the SIC, Airable partnered with Dynamic Green Products and DeWalt to successfully develop a more environmentally friendly bar and chain oil for the tool manufacturer. Before introducing a soy-based product, customers wanting a petroleum alternative had experimented with vegetable oil. That tended to go solid and gum up power tools.

As for the soy-based alternative? The sales numbers speak for themselves.

“DeWalt’s bar and chain oil is now No. 1 overall on Amazon’s best-selling bar and chain oil list,” McGraw says. “It’s available and selling well in 1,500 Home Depot stores nationwide, as well as other online platforms and brick-and-mortar locations. In its inaugural year, we project that a single product will generate a demand of 55,000 bushels.”

Those success stories speak to the fact that soy innovation is only beginning.

“Soy is a remarkable commodity that can be used for a wide variety of applications,” Main says. “Our partnerships with leading research facilities in Illinois, universities and financial institutions position us well as we work to make Illinois a center of the emerging ag tech economy.”

What’s Ahead for the SIC

In 2025, the SIC will be managed out of ISA’s Lombard offices and staffed by members of the Market Development team, Main explains. Funding for its operations comes from ISA and other partners.

Diverse collaborations will explore commercialization opportunities from every angle.

“We are working with a wide range of partners including the USDA Agricultural Research Service lab in Peoria, the Illinois Innovation Network of state universities, and private-sector companies,” Main says. “They are contributing to the research and development of products in the five areas we are focusing on.”

In spring 2025, several big milestones are expected at the SIC. Among other priorities, Main says, ISA and its partners will:

- Launch a new research competition

- License the SIC’s biolubricant for commercial development

- Complete R&D on two more commercially viable products

“The SIC is a great example of the vision and leadership that Illinois soybean farmers bring to the table,” Main says. “As the No. 1 soybean-producing state, we need to continually look for ways to innovate and diversify. Our goal is to grow new markets and support the efforts of the world’s most successful agricultural producers.”

Airable’s McGraw similarly sees the SIC as a hub for centralizing all Illinois soybean stakeholders and research resources for future growth of the industry.

“I fully expect that Airable and the Center, in parallel and in collaboration, will continue earning and growing our reputation as leaders in soy-based innovation,” McGraw says. “That recognition will attract more collaborators and more resources, which will lead not only to more soy-based products but also to the elevation of soy as an optimal alternative to incumbent feedstocks. Soy sales will rise, demand will rise and it all goes back to the farmer. Perhaps one day, soy as a feedstock will become its own industry, bringing additional economic benefits to rural areas.”

Pitstick acknowledges that not all of the SIC’s benefits will be apparent overnight. Instead, he and other Illinois soybean farmers can view the effort as an investment in the present and future of the soy economy.

“It’s not an instant gratification,” he says. “Some of the stuff might take two to five years. But if we can create demand for 10 million bushels, that’s huge. As a soy checkoff and association, we need to find that 10-million-bushel growth every year just to keep up with supply.”

Pitstick encourages Illinois farmers to get involved in participating on the ISA board and in other volunteer opportunities so their ideas can be heard and put to work.

“The farmer boards of 20 years ago were mostly retired farmers,” Pitstick recalls. “The boards of today are much younger and sometimes have off-farm experience. Bringing all that knowledge together really builds a much more dynamic board because of that level of education.”

With the support of Illinois farmers and a deep bench of other experts and partners, the Center is poised to play an exciting role at the forefront of soy product commercialization for years to come.

Recent Articles

Did you know soy can be used to replace nearly any product made from petroleum—including plastics? Soy-based plastics offer a nontoxic alternative to everyday items, contributing to sustainability and representing an exciting opportunity to drive demand for Illinois soy.

By Dylan Karis, Lead Chemist, Airable Research Lab

Learn more about an emerging partnership between ISA and the Peoria-based National Center for Agricultural Utilization, a 270,000-sq.-ft. research facility that employs nearly 200 people including 75 Ph.D. scientists.

By IL Field & Bean Team